| Scientific Equipments & Products |

|

|

| Forces Apparatus: |

| Forces Apparatus Manufacturers - Funicular Polygon and Forces Apparatus, Shearing Force Apparatus, Bending Moment Apparatus and Work done by a Variable Force (Tangential Effort) |

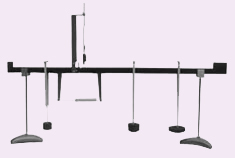

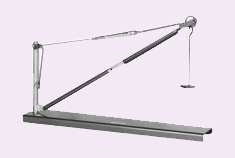

Funicular Polygon and Forces Apparatus Funicular Polygon and Forces Apparatus

Low cost, effective teaching

Self-contained, bench mounted

Direct measurement of forces

Adjustable lines of action of forces

Practical verification of triangle of forces, polygon of forces and link polygon

Demonstrates equilibrium of forces at a point, applied to various points round a

disc or acting on a rectangular lamina

Concurrent & Non-concurrent coplanar forces

Three year warranty

Range of Experiments

- To resolve by experiment any suitable system of static coplanar forces which may or may not be concurrent

- To verify graphically using:

a) triangle of forces for three concurrent coplanar forces

b) polygon of forces for more than three concurrent coplanar forces

c) link polygon for three or more non-concurrent coplanar forces

- To investigate (c) for either a disc or a rectanglar shape

- To compare the accuracy of the experiment by comparing the experimental and graphical results

Description

This

apparatus is a more comprehensive and versatile version of the HFC2. A

simple but elegant demonstration of the conditions of equilibrium for

three or more coplanar forces acting either at a point, on a circular

disc or on a rectangular shape. Up to five loads can be applied to the

chosen shape by setting up pulleys at various angular positions. The

lines of action of the forces are recorded by drawing along the weighted

cords onto a piece of paper attached to the pulley table. A range of

experiments is possible, investigating concurrent and non concurrent

coplanar forces acting on simple shapes, comparing the experimental

values with the relevant polygons of force.

This equipment is

part of a range designed to both demonstrate and experimentally confirm

basic engineering principles. Great care has been given to each item so

as to provide wide experimental scope without unduly complicating or

compromising the design. Each piece of apparatus is self-contained and

compact. Setting up time is minimal, and all measurements are made with

the simplest possible instrumentation, so that the student involvement

is purely with the engineering principles being taught. A complete

instruction manual is provided describing the apparatus, its

application, experimental procedure and typical test results.

|

|

| |

|

| |

Shearing Force Apparatus Shearing Force Apparatus

Features

- Low cost, effective teaching

- Self-contained

- Bench mounted

- Direct measurement of Shear Force

- Loads and supports can be placed in

any position

- Visual practical verification of the

concept of Shear Force

- Allows investigation of stability and

influence lines

- Reinforces concept of equilibrium of vertical forces & moments

- Three year warranty

Range of Experiments

- To comprehend the action of shear in a beam

- To measure the shearing force at a section of a loaded beam, and to compare with a theoretical estimate

- To study the definition of an influence line for shear force

Description

A

length of material supported horizontally and carrying vertical loads

is called a beam. The loading causes bending and transverse shearing.

The loads and reactions are the 'external' forces acting on the beam.

They must be in equilibrium. However, the strength of the beam depends

on 'internal' forces. This experiment demonstrates the nature of these

internal forces and their dependence on the external system of forces.

The

experimental beam is in two parts, joined by a pair of ball bearing

rollers running in flat vertical tracks. To develop the internal beam

forces at the section an underslung tension spring is used to resist the

bending moment, while an overhung spring balance provides the vertical

shearing force. Due to the mechanical arrangement, there must always be a

net downward load on the longer side of the split beam.

The beam

is simply supported on end bearings and several weight hangers can be

attached at any position on either side of the joint. A hinged metal

strip is available to simulate the loading pattern of a panelled girder

for a more advanced experiment on influence lines.

This equipment

is part of a range designed to both demonstrate and experimentally

confirm basic engineering principles. Great care has been given to each

item so as to provide wide experimental scope without unduly

complicating or compromising the design. Each piece of apparatus is

self-contained and compact. Setting up time is minimal, and all

measurements are made with the simplest possible instrumentation, so

that the student involvement is purely with the engineering principles

being taught. A complete instruction manual is provided describing the

apparatus, its application, experimental procedure and typical test

results. |

|

| |

|

| |

|

|

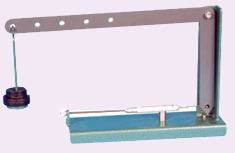

Bending Moment Apparatus Bending Moment Apparatus

Features

- Low cost, effective teaching

- Self-contained

- Bench mounted

- Experimental determination of bending

moment at a beam section

- Loads and supports can be placed in

any position

- Visual vertification of the nature of

bending moment

- Allows investigation of stability and

influence lines

- Reinforces concept of equilibrium of

vertical forces and moments

- Three year warrant

Range of Experiments

- To comprehend the action of moment of resistance in a beam

- To measure the bending moment at a section of a loaded beam and to compare with a theoretical estimate

- To study the definition of an influence line for bending moment

Description

A

length of material supported horizontally and carrying vertical loads

is called a beam. The loading causes bending and transverse shearing.

The loads and reactions are the 'external' forces acting on the beam.

They must be in equilibrium. However, the strength of the beam depends

on 'internal' forces or moments. This experiment demonstrates the nature

of these internal forces and their dependence on the external system of

forces.

The experimental beam is in two parts, joined together

by a pair of low friction ball bearings. An underslung spring balance

provides a resisting moment, and also allows the section bending moment

to be measured. A hinged metal strip to simulate the loading pattern of

panelled girder for a more advanced experiment on influence lines is

available.

The beam is simply supported on end bearings and

several weight hangers can be attached at any position on either side of

the hinge.

This equipment is part of a range designed to both

demonstrate and experimentally confirm basic engineering principles.

Great care has been given to each item so as to provide wide

experimental scope without unduly complicating or compromising the

design. Each piece of apparatus is self-contained and compact. Setting

up time is minimal, and all measurements are made with the simplest

possible instrumentation, so that the student involvement is purely with

the engineering principles being taught. A complete instruction manual

is provided describing the apparatus, its application, experimental

procedure and typical test results. |

|

| |

|

| |

|

|

Work done by a Variable Force (Tangential Effort) Work done by a Variable Force (Tangential Effort)

Features

- Low cost, effective teaching

- Self-contained

- Bench mounted

- Reinforces concepts of work and energy

- Direct reading of tangential effort

- Three year warranty

Range of Experiments

- To

obtain the experimental relationship between effort and distance moved

by effort, and to compare with a theoretical prediction

- To show that the work done is the area under a graph of load against distance moved

Description

This

experiment is designed to reinforce the general principle that the work

done, particularly by a variable force, can be determined simply by

measuring the area under the graph of force and distance moved. The

equipment is deliberately simple so that concepts are readily grasped.

It is a companion experiment to HFC6, which is concerned with the work

done by available vertical force.

A pivoted arm carrying a weight

at its end is restrained by a spring balance at right angles to the

arm. The angular position of the arm is indicated by a protractor scale.

The

effort is the force needed to hold the weighted arm at a particular

angle. This can be repeated for several different weights.

This

equipment is part of a range designed to both demonstrate and

experimentally confirm basic engineering principles. Great care has been

given to each item so as to provide wide experimental scope without

unduly complicating or compromising the design. Each piece of apparatus

is self-contained and compact. Setting up time is minimal, and all

measurements are made with the simplest possible instrumentation, so

that the student involvement is purely with the engineering principles

being taught. A complete instruction manual is provided describing the

apparatus, its application, experimental procedure and typical test

results. |

|

| |

|

| |

|

|

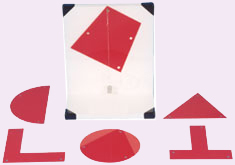

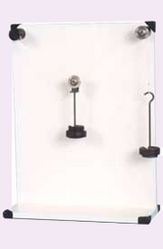

Centre of Gravity Apparatus Centre of Gravity Apparatus

Features

- Low cost, effective teaching

- Self-contained

- Bench mounted

- Six different shapes

- Direct location of Centre of Gravity by drawing

- Three year warranty

Range of Experiments

- To

establish the position of the centre of gravity of several different

shapes by experiment, and to compare with values derived from

calculation or reference books

Description

The

centre of gravity of a shape of uniform thickness can easily be found by

this method. It provides a simple technique for complicated shapes, far

quicker than by using calculus for example, although not producing an

accurate answer to the handling of a yacht, the calculation of the

moments caused by the wind and water acting at the 'centre of lateral

area' of the sails and keel are still used as a starting point.

A

free standing backboard has a pin from which a selection of flat shapes

can be hung. A simple pendulum suspended from the pin enables the line

of action of the weight to be transferred to the lamina. The centre of

gravity is the position on the shape where two or more such lines

intersect.

This equipment is part of a range designed to

both demonstrate and experimentally confirm basic engineering

principles. Great care has been given to each item so as to provide wide

experimental scope without unduly complicating or compromising the

design. Each piece of apparatus is self-contained and compact. Setting

up time is minimal, and all measurements are made with the simplest

possible instrumentation, so that the student involvement is purely with

the engineering principles being taught. A complete instruction manual

is provided describing the apparatus, its application, experimental

procedure and typical test results. |

|

| |

|

| |

|

|

Bell Crank Lever Bell Crank Lever

Features

- Low cost, effective teaching

- Self-contained

- Bench mounted

- 5 different lever ratio

- Direct readout of reaction by

spring balance

- Three year warranty

Range of Experiments

- To determine by experiment the reaction force of a bell-crank lever to an applied load

- To confirm the effect of leverage ratio

- To compare with calculation by taking moments about the pivot

Description

Lever

mechanisms of all shapes and sizes are very common parts of machines,

particularly in hand operated devices. The bell crank lever offers the

typical mechanical advantage of a lever, and in addition it turns the

line of action of the effort through 90°. In most cases the cranked

lever would be a casting with a bushed pivot at the corner. The

experimental model has been built up from plastic to simulate the real

thing.

This traditional item enables the reaction force of a 90°

bell crank to be measured by a spring balance when a load is applied at

any of five leverage ratios.

The bell crank is supported on a bushed pivot.

This

equipment is part of a range designed to both demonstrate and

experimentally confirm basic engineering principles. Great care has been

given to each item so as to provide wide experimental scope without

unduly complicating or compromising the design. Each piece of apparatus

is self-contained and compact. Setting up time is minimal, and all

measurements are made with the simplest possible instrumentation, so

that the student involvement is purely with the engineering principles

being taught. A complete instruction manual is provided describing the

apparatus, its application, experimental procedure and typical test

results. |

|

| |

|

| |

|

|

Centrifugal Force Apparatus Centrifugal Force Apparatus

Features

- Low cost, effective teaching

- Self-contained

- Wall mounted

- Speed, rotating mass, and radius of

gyration independently variable

- Direct readout of centrifugal force by

spring balance

- Direct readout of rotational speed by

digital tachometer

- Fully guarded

- Three year warranty

Range of Experiments

- To verify that the centrifugal force on a rotating mass is proportional to the:-

- square of the speed

- mass

- radius of gyration

- To compare the experimental results with those calculated from theory

Description

This

apparatus is used to verify that centrifugal force varies with the

square of the speed, the rotating mass, and the radius of gyration. A

unique feature is that all three variables can be set and the

centrifugal force directly read from the spring balance. Six masses are

supplied. The unit has a built-in variable speed drive and digital

tachometer.

The equipment is fully guarded (not shown in the photograph).

This

equipment is part of a range designed to both demonstrate and

experimentally confirm basic engineering principles. Great care has been

given to each item so as to provide wide experimental scope without

unduly complicating or compromising the design. Each piece of apparatus

is self-contained and compact. Setting up time is minimal, and all

measurements are made with the simplest possible instrumentation, so

that the student involvement is purely with the engineering principles

being taught. A complete instruction manual is provided describing the

apparatus, its application, experimental procedure and typical test

results. |

|

| |

|

| |

|

|

Conservation of Angular Momentum Conservation of Angular Momentum

Features

- Low cost, effective teaching

- Self-contained

- Wall mounted

- High visual impact

- Genuine "hands-on" experience

- Three year warranty

Range of Experiments

- Used

for demonstration only, no measurements are intended. Demonstrates

basic concepts of conservation of angular momentum through visual

observation

Description

Conservation of linear

momentum is well understood and often demonstrated to students. Equally

important is the conservation of angular momentum. It is not easy to do

meaningful experiments on this, but a highly visual demonstration of

almost dramatic impact is the effect of reducing the radius of a

rotating mass. This is often seen in an ice skater performing a

pirouette. First they spin round on an axis corresponding to their body,

arms outstretched. When they raise their arms above their head, the

increase in spin in considerable. Rather than go to an ice rink,

students can perform this experiments in the laboratory.

A bench

mounted vertical board has a rotating arm along which two weights can be

moved by a pull cord operated by the student or demonstrator.

The

weights are moved to the outer ends of their travel, away from the

centre of rotation. The arm is then spun rapidly by hand, and the

weights pulled towards the centre by the cord.

The resulting increase in angular velocity is considerable.

This

equipment is part of a range designed to both demonstrate and

experimentally confirm basic engineering principles. Great care has been

given to each item so as to provide wide experimental scope without

unduly complicating or compromising the design. Each piece of apparatus

is self-contained and compact. Setting up time is minimal, and all

measurements are made with the simplest possible instrumentation, so

that the student involvement is purely with the engineering principles

being taught. A complete instruction manual is provided describing the

apparatus, its application, experimental procedure and typical test

results. |

|

| |

|

| |

|

|

Forces Apparatus Forces Apparatus

Features

- Low cost, effective teaching

- Self-contained

- Wall mounted

- Evaluation of forces in levers and slings

for lifting heavy objects

- Three year warranty

Range of Experiments

- Reactions of levers

- Forces acting at an angle

- Forces at a point

- Finding centres of gravity

Description

For

forces on levers, sling forces, equilibrium forces, etc and

particularly suitable for motor vehicle courses. All components for the

above experiments are supplied as standard. Five geometric shapes with a

simple pendulum can be supplied as an optional extra for centre of

gravity experiments.

This equipment is part of a range designed

to both demonstrate and experimentally confirm basic engineering

principles. Great care has been given to each item so as to provide wide

experimental scope without unduly complicating or compromising the

design. Each piece of apparatus is self-contained and compact. Setting

up time is minimal, and all measurements are made with the simplest

possible instrumentation, so that the student involvement is purely with

the engineering principles being taught. A complete instruction manual

is provided describing the apparatus, its application, experimental

procedure and typical test results. |

|

| |

|

| |

|

|

Three Wire Suspension Apparatus Three Wire Suspension Apparatus

Features

- Low cost, effective teaching

- Self-contained

- Bench mounted

- Direct measurement of horizontal reaction

- Angle of toggle variable

- Demonstrates application of velocity

diagrams

- Three year warranty

Range of Experiments

- To study the vertical equilibrium of a two and three wire suspension system

- To examine the action of the central vertical redundant force

Description

A

free standing backboard provides supports for three tensile suspenders

that meet at a ring carrying a load hanger. Spring balances measure the

tension in each of the suspenders which are at about 30 and 45 degrees

to the central vertical one. The lengths of each suspender can be

adjusted by a threaded rod attached to the spring balance.

This

equipment is part of a range designed to both demonstrate and

experimentally confirm basic engineering principles. Great care has been

given to each item so as to provide wide experimental scope without

unduly complicating or compromising the design. Each piece of apparatus

is self-contained and compact. Setting up time is minimal, and all

measurements are made with the simplest possible instrumentation, so

that the student involvement is purely with the engineering principles

being taught. A complete instruction manual is provided describing the

apparatus, its application, experimental procedure and typical test

results. |

|

| |

|

| |

|

|

Toggle Joint Apparatus Toggle Joint Apparatus

Features

- Low cost, effective teaching

- Self-contained

- Bench mounted

- Direct measurement of horizontal reaction

- Angle of toggle variable

- Demonstrates application of

velocity diagrams

- Three year warranty

Range of Experiments

- To determine the experimental horizontal reaction due to loading

- To compare with theoretical predictions, such as the velocity diagram technique

- To assess the effect of the toggle angle

Description

This

apparatus is designed to evaluate forces within a toggle mechanism.

Load is applied to the two pairs of links by a hanger suspended from

their connecting pivot. One end of the links is pivoted to a base, and

the other end is able to move sideways on low friction ball bearing

wheels. The moving links are restrained by a horizontal spring balance,

which measures the horizontal reaction directly. The angle of the toggle

can be varied. Adjustment is provided for returning the geometry of the

loaded toggle to its original unloaded state before taking

measurements. The supporting blocks are not supplied.

There are

many ways in which the forces can be determined theoretically. The

instruction sheet provided with the apparatus takes the opportunity to

introduce the use of velocity diagrams to solve essentially static

problems by considering virtual motion. However, other techniques can be

used if desired.

This equipment is part of a range designed to

both demonstrate and experimentally confirm basic engineering

principles. Great care has been given to each item so as to provide wide

experimental scope without unduly complicating or compromising the

design. Each piece of apparatus is self-contained and compact. Setting

up time is minimal, and all measurements are made with the simplest

possible instrumentation, so that the student involvement is purely with

the engineering principles being taught. A complete instruction manual

is provided describing the apparatus, its application, experimental

procedure and typical test results. |

|

| |

|

| |

|

|

Shear Legs Shear Legs

- Low cost, effective teaching

- Self-contained

- Bench mounted

- Direct measurement of strut and backstay forces by spring balance

- Three year warranty

Range of Experiments

- Experimental determination of forces in shear legs

- Comparison with theoretical prediction

- To assess the effect of changing the shear leg geometry

Description

Shear

legs are often used to make temporary cranes. In this experiment the

ideas developed in experiments with several forces in one plane are

extended to three dimensions. Clarity of thought is encouraged, since

there are both compressive and tensile forces present.

The double

shear legs are mounted on rollers which run on a round bar. Compression

forces in the legs are measured with integral spring balances, and

restraint is by an adjustable tie chain. The back stay is adjustable and

is also fitted with a spring balance. Loading is by a weight hung from

the apex.

The unit is free standing on a bench top.

This

equipment is part of a range designed to both demonstrate and

experimentally confirm basic engineering principles. Great care has been

given to each item so as to provide wide experimental scope without

unduly complicating or compromising the design. Each piece of apparatus

is self-contained and compact. Setting up time is minimal, and all

measurements are made with the simplest possible instrumentation, so

that the student involvement is purely with the engineering principles

being taught. A complete instruction manual is provided describing the

apparatus, its application, experimental procedure and typical test

results. |

|

| |

|

| |

|

|

Tension Coefficients Apparatus Tension Coefficients Apparatus

Features

- Low cost, effective teaching

- Self-contained

- Wall mounted

- Direct reading of jib and tie loads using spring balances

- Demonstrates the application of tension coefficient to evaluate forces in three dimensions

Range of Experiments

- To determine experimentally forces induced in individual frame members

- To calculate the theoretical forces induced, using the method of tension coefficients

- To compare the experimental and theroretical results

- To repeat for other frame configurations

Description

The

apparatus consists of a jib restrained by two chain ties making a

triangulated three dimensional structure. The jib and both ties are

fitted with spring balances so that the internal forces can be measured.

The

bottom of the jib is pivoted to the wall mounted plate and the tie

attachment locations can be varied independently at their wall ends.

A

load is hung from the jib end, and the geometry returned to its

unloaded state using a knurled collar before taking the spring balance

readings.

This equipment is part of a range designed to both

demonstrate and experimentally confirm basic engineering principles.

Great care has been given to each item so as to provide wide

experimental scope without unduly complicating or compromising the

design. Each piece of apparatus is self-contained and compact. Setting

up time is minimal, and all measurements are made with the simplest

possible instrumentation, so that the student involvement is purely with

the engineering principles being taught. A complete instruction manual

is provided describing the apparatus, its application, experimental

procedure and typical test results. |

|

| |

|

| |

|

|

Rubber in Shear Apparatus Rubber in Shear Apparatus

Features

- Low cost, effective teaching

- Self-contained

- Wall mounted

- Range of pivot angles supplied

- Optional bearings available

- Determination of modulus of rigidity and Poissons Ratio

- Three year warranty

Range of Experiments

- To determine the variation of deflection with applied load

- To investigate the relationship between shear stress and shear strain

- To find the modulus of rigidity of the rubber block

Description

Rubber

blocks in shear force are often used on engine and in equipment

mounting to isolate vibrations. They do this by absorbing shock energy

by deforming. This deformation leads to a decrease in cross-section as

the block lengthens, an effect described by Poisson's Ratio. After this

experiment, students will understand the behaviour of a very flexible

material such as rubber. Rubber is interesting in that the lay person

regards it as an 'elastic' material. In engineering terms it is not as

'elastic' as steel and often exhibits a high degree of hysteresis.

A

rubber block 150 x 75 x 25mm is bonded to two aluminium alloy plates.

One plate is screwed to a wall, whilst the other has a shear load

applied by a loaded weight hanger. A dial gauge measures the deflection

of the block.

This equipment is part of a range designed to both

demonstrate and experimentally confirm basic engineering principles.

Great care has been given to each item so as to provide wide

experimental scope without unduly complicating or compromising the

design. Each piece of apparatus is self-contained and compact. Setting

up time is minimal, and all measurements are made with the simplest

possible instrumentation, so that the student involvement is purely with

the engineering principles being taught.

A complete instruction

manual is provided describing the apparatus, its application,

experimental procedure and typical test results. |

|

| |

|

| |

|

|

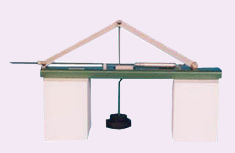

Basic Roof Truss Basic Roof Truss

Features

- Low cost, effective teaching

- Self-contained

- Bench mounted

- Truss angle can be varied

- Direct read out of strut and tie forces by spring balances

- Three year warranty

Range of Experiments

- To compare experimental values of the forces in the struts and tie of a basic roof truss with theoretical predictions

- To observe the effect of changing the tie bar length

Description

The

basic roof truss consists of two rafters or struts and a restraining

tie. Both rafters are pivoted at their apex. The other end of one of the

rafters is pivoted to a free standing base, whilst the remaining rafter

end runs on ball bearings along a track. When a load is hung from the

apex, the free end of the rafter moves sideways, restrained by a spring

balance tie.

Both rafters also include spring balances so that all internal loads can be directly measured.

Re-adjustment

of the geometry back to its original unloaded configuration is easily

made before taking measurements. The length of the tie can be varied to

change the angles of the truss.

This equipment is part of a range

designed to both demonstrate and experimentally confirm basic

engineering principles. Great care has been given to each item so as to

provide wide experimental scope without unduly complicating or

compromising the design. Each piece of apparatus is self-contained and

compact. Setting up time is minimal, and all measurements are made with

the simplest possible instrumentation, so that the student involvement

is purely with the engineering principles being taught. A complete

instruction manual is provided describing the apparatus, its

application, experimental procedure and typical test results. |

|

| |

|

| |

|

|

Derrick Crane Derrick Crane

Features

- Low cost, effective teaching

- Self-contained

- Bench mounted

- Direct readout of jib and tie loads by spring balances

- Demonstrate principles of equilibrium and polygon of forces

- Three year warranty

Range of Experiments

- Determination of forces in the crane members

- Comparison with prediction by the polygon of forces

- Demonstration of equilibrium of forces

Description

This

apparatus represents the forces in a simple crane and introduces the

student to equilibrium of forces and solution by the triangle of forces.

The crane is mounted on a base designed to be stood on a level bench.

Both the jib and tie include spring balances for measuring the internal forces. A load is hung from the end of the jib.

Re-adjustment

of the crane geometry back to its original unloaded layout is possible

by a knurled adjuster on the jib and adjusting the links of the chain.

This

equipment is part of a range designed to both demonstrate and

experimentally confirm basic engineering principles. Great care has been

given to each item so as to provide wide experimental scope without

unduly complicating or compromising the design. Each piece of apparatus

is self-contained and compact. Setting up time is minimal, and all

measurements are made with the simplest possible instrumentation, so

that the student involvement is purely with the engineering principles

being taught. A complete instruction manual is provided describing the

apparatus, its application, experimental procedure and typical test

results. |

|

| |

|

| |

|

|

Work done by a Variable Force (Vertical Effort) Work done by a Variable Force (Vertical Effort)

Features

- Low cost, effective teaching

- Self-contained

- Bench mounted

- Reinforces concepts of work and energy

- Three year warranty

Range of Experiments

- To determine the work done by a variable effort and to compare with the work done in lifting the load

- To show that the work done by the effort is equal to the change in potential energy of the load

Description

This

experiment is designed to reinforce the general principle that the work

done, particularly by a variable force, can be determined simply by

measuring the area under the graph of force and distance moved. It forms

a comparison experiment with HFC7 which is concerned with the work done

by a variable tangential force.

The experiment is deliberately

simple so that theoretical comparisons are easily made. It forms a good

introduction to simple machines, leading to later studies on machine

performance.

The apparatus is a simple lifting mechanism with

obvious non linear characteristics. A suspension cord carrying a loaded

trolley at mid span is tensioned by passing the cord over a pulley at

one end and down to a weight hanger. As the vertical effort is

increased, the tensioned cord will move to a new equilibrium position

lifting the loaded trolley. Heights of the load and effort are measured

relative to the base.

All the pulleys are fitted with ball bearings to minimise friction effects.

This

equipment is part of a range designed to both demonstrate and

experimentally confirm basic engineering principles. Great care has been

given to each item so as to provide wide experimental scope without

unduly complicating or compromising the design. Each piece of apparatus

is self-contained and compact. Setting up time is minimal, and all

measurements are made with the simplest possible instrumentation, so

that the student involvement is purely with the engineering principles

being taught. A complete instruction manual is provided describing the

apparatus, its application, experimental procedure and typical test

results. |

|

| |

|

| |

|

|

Simple Moments Apparatus Simple Moments Apparatus

Features

- Low cost, effective teaching

- Self-contained

- Bench mounted

- Demonstrates concept of moment

equilibrium

- Three year warranty

Range of Experiments

- To apply a stable system of loading to a pivoted beam

- To compare with values obtained from calculation using simple moments

Description

This

equipment provides a simple easy to understand experiment on the

equilibrium of moments. Several loads can be put on the beam at various

positions. These will make the beam rotate. The student has to determine

the moment necessary to overcome this rotation and keep the beam level.

On a practical level, this principle is used in the measurement of

goods, such as in chemical balances and steelyards.

The alloy

beam is 530mm long and graduated in each direction from the central

pivot in cm. Three wire stirrups, weight hangers and a set of weights

are included.

This equipment is part of a range designed to both

demonstrate and experimentally confirm basic engineering principles.

Great care has been given to each item so as to provide wide

experimental scope without unduly complicating or compromising the

design. Each piece of apparatus is self-contained and compact. Setting

up time is minimal, and all measurements are made with the simplest

possible instrumentation, so that the student involvement is purely with

the engineering principles being taught. A complete instruction manual

is provided describing the apparatus, its application, experimental

procedure and typical test results. |

|

| |

|

| |

|

|

Wall Jib Crane Wall Jib Crane

Features

- Member forces all directly measured

- Rapidly variable configuration

- Wall mounted

- Folds flat to the wall

- Three year warranty

Range of Experiments

- Comparison of measured forces with a triangle of forces and theoretical values

- Comprehension of the action of the crane cable forces on the jib and the effect of the jib inclination

Description

Although

wall jib cranes are obsolete, the self evident confluence of the four

forces at the end of the jib illustrates the application of a triangle

of forces so clearly to a real situation that this is an invaluable

lesson.

This wall mounted self-contained jib crane has spring

balances built into its two members. After loading the member lengths

can be adjusted to their no-load lengths. The jib out-hang and the crane

cable inclination can be readily changed. An instruction sheet is

provided.

This equipment is part of a range designed to both

demonstrate and experimentally confirm basic engineering principles.

Great care has been given to each item so as to provide wide

experimental scope without unduly complicating or compromising the

design. Each piece of apparatus is self-contained and compact. Setting

up time is minimal, and all measurements are made with the simplest

possible instrumentation, so that the student involvement is purely with

the engineering principles being taught. A complete instruction manual

is provided describing the apparatus, its application, experimental

procedure and typical test results. |

|

| |

|

| |

|

|

Acceleration Apparatus Acceleration Apparatus

Features

- Self-contained

- Bench mounted

- Novel gliding design

- Total mass of moving system can be kept constant for different acceleration masses

- Acceleration determination by spark generator and electro-sensitive paper

- Confirmation of Newton's Second Law

of Motion

- Determination of gravitational acceleration

- Three year warranty

Range of Experiments

- To show that a force causes a mass to accelerate, and that the acceleration is proportional to the force

- To compare experimental and theoretical values of forces required to accelerate a given mass

- To determine the acceleration due to gravity, g

Description

This

type of equipment has been used for many years to introduce students to

accelerated linear motion, in particular the dependence of the

acceleration on the net force causing the motion. Confirmation of

Newton's second law of motion and the determination of gravitational

acceleration are possible.

The trolley which carries five removable masses glides on two rails attached to the base.

Electro-sensitive

paper strip attached to the trolley passes through a spark generator

which produces five impulses per second, enabling the trolley

acceleration to be accurately determined.

The weights which produce the accelerating force are hung directly onto the paper strip.

All required equipment is supplied. Further rolls of electro-sensitive paper are available.

This

equipment is part of a range designed to both demonstrate and

experimentally confirm basic engineering principles. Great care has been

given to each item so as to provide wide experimental scope without

unduly complicating or compromising the design. Each piece of apparatus

is self-contained and compact. Setting up time is minimal, and all

measurements are made with the simplest possible instrumentation, so

that the student involvement is purely with the engineering principles

being taught. A complete instruction manual is provided describing the

apparatus, its application, experimental procedure and typical test

results |

|

| |

|

| |

|

|

Fletcher's Trolley Fletcher's Trolley

Features

- Traditional design

- Self-contained

- Bench mounted

- Total mass of moving system can be maintained constant for different

acceleration masses

- Five trolley masses

- Acceleration determination by ink trace

- Confirmation of Newton's Second Law

of Motion

- Determination of Gravitational Acceleration

- Three year warranty

Range of Experiments

- To show that a force causes a mass to accelerate, and that the acceleration is proportional to the force

- To compare experimental and theoretical values of forces required to accelerate a given mass

- To determine the acceleration due to gravity, g

Description

This

type of equipment has been used for many years to introduce students to

accelerated linear motion, in particular the dependence of the

acceleration on the net force causing the motion. Confirmation of

Newton's second law of motion and the determination of gravitational

acceleration are possible.

This strongly built traditional

apparatus produces very accurate results. The trolley has five removable

weights. During an experiment, the total mass of the moving equipment

can be maintained constant by transferring weights from the rear of the

trolley to the load hanger.

Acceleration is measured using an

inked brush attached to a vibrating arm. This traces out an oscillatory

trace on a piece of paper fixed to the trolley.

This equipment is

part of a range designed to both demonstrate and experimentally confirm

basic engineering principles. Great care has been given to each item so

as to provide wide experimental scope without unduly complicating or

compromising the design. Each piece of apparatus is self-contained and

compact. Setting up time is minimal, and all measurements are made with

the simplest possible instrumentation, so that the student involvement

is purely with the engineering principles being taught. A complete

instruction manual is provided describing the apparatus, its

application, experimental procedure and typical test results. |

|

| |

|

| |

|

|

Rolling Disc on Inclined Plane Rolling Disc on Inclined Plane

Features

- Low cost, effective teaching

- Self-contained

- Bench mounted

- Measurement of moment of inertia by

rolling and oscillation

- Three year warranty

Range of Experiments

To determine and compare the moment of inertia of a disc by three methods:-

- Motion down a plane

- Oscillating pendulum

- Calculation

Description

The

moment of inertia of a rolling object is the rotary analagy of mass and

governs the rotary acceleration. It can be determined in three ways; by

rolling, oscillation or calculation. All should ideally give the same

result but the student can be introduced to differences caused by

different experimental techniques

A pair of machined rails form

an inclined track for a disc rolling on a spindle through its centre.

The inclination of the track can be readily altered by raising an end

fitted with a height bar. Two discs are supplied; the larger has a

diameter of 150mm and a thickness of 22.5mm, whilst the smaller is 100mm

by 20mm. This enables two moments of inertia to be used.

The

moments of inertia of the discs are determined from the time taken for

the disc to roll down the slope. They may also be found from a

subsidiary experiment using an oscillating pendulum in which the disc

spindles are supported on knife edge bearings and a pendulum is attached

to the shaft. The moments of inertia are estimated from the periodic

time of the assembly.

This equipment is part of a range designed

to both demonstrate and experimentally confirm basic engineering

principles. Great care has been given to each item so as to provide wide

experimental scope without unduly complicating or compromising the

design. Each piece of apparatus is self-contained and compact. Setting

up time is minimal, and all measurements are made with the simplest

possible instrumentation, so that the student involvement is purely with

the engineering principles being taught. A complete instruction manual

is provided describing the apparatus, its application, experimental

procedure and typical test results. |

|

| |

|

| |

|

|

Reaction of Beams Apparatus Reaction of Beams Apparatus

Features

- Low cost, effective teaching

- Self-contained

- Bench mounted

- Direct measurement of reactions by

spring balances

- Loads and supports can be placed in

any position

- Practical verification of equilibrium of

vertical force or moments

- Simply supported beams or levers can

be set up

- Three year warranty

Range of Experiments

- Experimental determination of the reaction forces in the supports of a simply supported beam under various loadings

- Measurement of loads and moments on a lever

- Comparison with calculated results and validation of the principle of equilibrium

Description

A

horizontal length of material with a vertical load system is called a

beam. It is one of the most basic engineering ways of supporting a load.

External forces such as the applied loads and the beam support

reactions have to be in equilibrium. Given a loading system, the support

reactions can be calculated from force and moment equations.

This

apparatus is designed for simple experiments and demonstrations on

simply supported beams. Two spring balances act as supports and enable

reactions to be read directly. Three movable load hangers allow loads to

be put in a number of positions.

Levers can be investigated by suspending the beam from the free standing frame, and holding down the end with a spring balance.

This

equipment is part of a range designed to both demonstrate and

experimentally confirm basic engineering principles. Great care has been

given to each item so as to provide wide experimental scope without

unduly complicating or compromising the design. Each piece of apparatus

is self-contained and compact. Setting up time is minimal, and all

measurements are made with the simplest possible instrumentation, so

that the student involvement is purely with the engineering principles

being taught. A complete instruction manual is provided describing the

apparatus, its application, experimental procedure and typical test

results. |

|

| |

|

| |

|

|

Forces on a Beam Apparatus Forces on a Beam Apparatus

Features

- Low cost, effective teaching

- Self-contained

- Bench mounted

- Direct measurement of reactions by

scales

- Loads and supports can be placed in

any position

- Practical verification of equilibrium of

vertical force or moments

- Simply supported beams or levers

- Three year warranty

Range of Experiments

- Experimental determination of the reaction forces in the supports of a simply supported beam under various loadings

- Measurement of loads and moments on a lever

- Comparison with calculated results and validation of the principle of equilibrium

Description

A

horizontal length of material with a vertical load system is called a

beam. It is one of the most basic engineering ways of supporting a load.

External forces such as the applied loads and the beam support

reactions have to be in equilibrium. Given a loading system, the support

reactions can be calculated from force and moment equations.

This

apparatus is designed for simple experiments and demonstrations on

simply supported beams. Two scales act as supports and enable reactions

to be read directly. Two movable load hangers allow loads to be put in a

number of positions.

Levers can be investigated by placing the

beam across one of the scales. Different leverage ratios can be set up

using an adjustable tie rod which locates in one of three alternative

positions on the base plate. The force in the rod is measured by a

linear spring balance.

This equipment is part of a range designed

to both demonstrate and experimentally confirm basic engineering

principles. Great care has been given to each item so as to provide wide

experimental scope without unduly complicating or compromising the

design. Each piece of apparatus is self-contained and compact. Setting

up time is minimal, and all measurements are made with the simplest

possible instrumentation, so that the student involvement is purely with

the engineering principles being taught. A complete instruction manual

is provided describing the apparatus, its application, experimental

procedure and typical test results. |

|

| |

|

| |

|

|

Triangle of Forces Apparatus Triangle of Forces Apparatus

Features

- Low cost, effective teaching

- Self-contained

- Bench mounted

- Direct measurement of forces

- Adjustable lines of action of forces

- Practical verification of triangle of forces

- Three year warranty

Range of Experiments

- To find any suitable combination of three coplanar forces in equilibrium

- To compare the results with the graphical solution obtained by drawing the triangle of forces

- To demonstrate that th resultant of two known forces is equal and opposite to the equilibrant found experimentally

Description

A

bench mounted circular table with a central pin and 360º protractor has

three pulleys on adjustable clamps round the edge. Conditions of

equilibrium are obtained by centralising a small cord ring over the

central pin with cords to load hangers where the loads and lines of

action are variable.

The triangle of forces in equilibrium can be constructed and the resultant of two known forces can be found.

This

equipment is part of a range designed to both demonstrate and

experimentally confirm basic engineering principles. Great care has been

given to each item so as to provide wide experimental scope without

unduly complicating or compromising the design. Each piece of apparatus

is self-contained and compact. Setting up time is minimal, and all

measurements are made with the simplest possible instrumentation, so

that the student involvement is purely with the engineering principles

being taught. A complete instruction manual is provided describing the

apparatus, its application, experimental procedure and typical test

results. |

|

|

|

|

|