| Scientific Equipments & Products |

|

|

| Theory of Machines: |

| Theory of Machines Manufacturers - Wheel and Axle, Wheel and Differential

Axle, Worm and Wheel Single Start |

Wheel and Axle Wheel and Axle

Features

- Low cost, effective teaching

- Self-contained

- Wall mounted

- Introduction to simple machines

- Determination of velocity ratio mechanical advantage and efficiency

- Three year warranty

Range of Experiments

- Experimental determination of velocity ratio and comparison with calculated value

- Determination of variation with load of

Description

The

PVC dual diameter wheel has an axle supported on simple pivots in a

sturdy wall mounting bracket. Cords wound round the peripheries of the

wheels carry load hangers for the load and effort. A set of weights is

provided.

This equipment is part of a range designed to both

demonstrate and experimentally confirm basic engineering principles.

Great care has been given to each item so as to provide wide

experimental scope without unduly complicating or compromising the

design. Each piece of apparatus is self-contained and compact. Setting

up time is minimal, and all measurements are made with the simplest

possible instrumentation, so that the student involvement is purely with

the engineering principles being taught.

A complete instruction

manual is provided describing the apparatus, its application,

experimental procedure and typical test results. |

|

| |

|

| |

Wheel and Differential Axle Wheel and Differential Axle

Features

- Low cost, effective teaching

- Self-contained

- Wall mounted

- Introduction to simple machines

- Determination of velocity ratio mechanical advantage and efficiency

- Simple wheel or differential axle machine

- Three year warranty

Range of Experiments

- Experimental

determination of velocity ratio and comparison with calculated values

for simple wheel and differential axle machine

- Determination of variation with load of

- Limiting efficiency of the machine

Description

A

PVC wheel of 190 mm diameter is integral with a differential axle of

114 and 38 mm diameters. The shaft runs in bronze bearings in a sturdy

wall mounting bracket. The necessary cords and load hangers are provided

and weights are included. An additional load hanger is supplied to

enable the simple wheel and axle experiment htm2 to be performed

This

equipment is part of a range designed to both demonstrate and

experimentally confirm basic engineering principles. Great care has been

given to each item so as to provide wide experimental scope without

unduly complicating or compromising the design. Each piece of apparatus

is self-contained and compact. Setting up time is minimal, and all

measurements are made with the simplest possible instrumentation, so

that the student involvement is purely with the engineering principles

being taught.

A complete instruction manual is provided

describing the apparatus, its application, experimental procedure and

typical test results. |

|

| |

|

| |

|

|

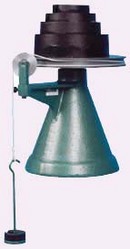

Worm and Wheel Single Start, 30:1 Ratio Worm and Wheel Single Start, 30:1 Ratio

Features

- Low cost, effective teaching

- Self-contained

- Wall mounted

- Introduction to simple machines

- Determination of velocity ratio mechanical advantage and efficiency

- Three year warranty

Range of Experiments

- Experimental determination of velocity ratio and comparison with calculated value

- Determination of variation with load of:

- effort

- friction

- efficiency

- Limiting efficiency of the machine

Description

This

high quality example of a steel worm and phosphor bronze wheel is built

on a substantial wall mounted base. Both worm and wheel have integral

cord drums with cords and load hangers to provide torque. The velocity

ratio of 30:1 is achieved by a single start worm.

This equipment

is part of a range designed to both demonstrate and experimentally

confirm basic engineering principles. Great care has been given to each

item so as to provide wide experimental scope without unduly

complicating or compromising the design. Each piece of apparatus is

self-contained and compact. Setting up time is minimal, and all

measurements are made with the simplest possible instrumentation, so

that the student involvement is purely with the engineering principles

being taught. A complete instruction manual is provided describing the

apparatus, its application, experimental procedure and typical test

results. |

|

| |

|

| |

|

|

Worm and Wheel 2 Start, 15:1 Ratio Worm and Wheel 2 Start, 15:1 Ratio

Features

- Low cost, effective teaching

- Self-contained

- Wall mounted

- Introduction to simple machines

- Determination of velocity ratio mechanical advantage and efficiency

- Three year warranty

Range of Experiments

- Experimental determination of velocity ratio and comparison with calculated value

- Determination of variation with load of:

- effort

- friction

- efficiency

- Limiting efficiency of the machine

Description

This

high quality example of a steel worm and phosphor bronze wheel is built

on a substantial wall mounted base. Both worm and wheel have integral

cord drums with cords and load hangers to provide torque. The velocity

ratio of 15:1 is achieved by a two start worm.

This equipment is

part of a range designed to both demonstrate and experimentally confirm

basic engineering principles. Great care has been given to each item so

as to provide wide experimental scope without unduly complicating or

compromising the design. Each piece of apparatus is self-contained and

compact. Setting up time is minimal, and all measurements are made with

the simplest possible instrumentation, so that the student involvement

is purely with the engineering principles being taught. A complete

instruction manual is provided describing the apparatus, its

application, experimental procedure and typical test results.

|

|

| |

|

| |

|

|

Simple Screw Jack Simple Screw Jack

Features

- Low cost, effective teaching

- Self-contained

- Bench mounted

- Introduction to simple machines

- Determination of velocity ratio mechanical advantage and efficiency

- Overhauling

- Three year warranty

Range of Experiments

- Experimental determination of velocity ratio and comparison with calculated value

- Determination of variation with load of:

- 1. effort

- 2. friction

- 3. efficiency

- Limiting efficiency of the machine

Description

This

simple screw jack is a 220 mm diameter turntable fitted with a 30 mm x 6

mm pitch screw is supported in a heavy cast iron base. The apparatus is

stood on a firm bench and a cord and weight hanger are wound round the

rim of the turntable and hung over the pulley. The pulley runs on ball

bearings to reduce friction to a minimum.

This equipment is part

of a range designed to both demonstrate and experimentally confirm basic

engineering principles. Great care has been given to each item so as to

provide wide experimental scope without unduly complicating or

compromising the design. Each piece of apparatus is self-contained and

compact. Setting up time is minimal, and all measurements are made with

the simplest possible instrumentation, so that the student involvement

is purely with the engineering principles being taught. A complete

instruction manual is provided describing the apparatus, its

application, experimental procedure and typical test results.

|

|

|

|

Wall Mounted Screw Jack Wall Mounted Screw Jack

Features

- Low cost, effective teaching

- Self-contained

- Wall mounted

- Introduction to simple machines

- Determination of velocity ratio mechanical advantage and efficiency

- Comparative efficiency of square and

Vee form threads

- Three year warranty

Range of Experiments

- Experimental determination of velocity ratio and comparison with calculated value

- Determination of variation with load of:

- effort

- friction

- efficiency

- Limiting efficiency of the machine

- Comparison of relative efficiency of Vee and Square thread forms

Description

The experimental screw jack mechanism is built on a sturdy wall bracket

The

shaft of the 200mm diameter turntable has both square and Vee form

threads of 24mm x 3mm pitch. The load hanger can be suspended from a

yoke from either of the nuts. Torque is applied to the turntable through

two "effort" hangers, and can be arranged to either lift or lower the

load.

This equipment is part of a range designed to both

demonstrate and experimentally confirm basic engineering principles.

Great care has been given to each item so as to provide wide

experimental scope without unduly complicating or compromising the

design. Each piece of apparatus is self-contained and compact. Setting

up time is minimal, and all measurements are made with the simplest

possible instrumentation, so that the student involvement is purely with

the engineering principles being taught. A complete instruction manual

is provided describing the apparatus, its application, experimental

procedure and typical test results.

|

|

|

|

Efficiency of Screw Threads Efficiency of Screw Threads

Features

- Low cost, effective teaching

- Self-contained

- Wall mounted

- Introduction to simple machines

- Determination of velocity ratio mechanical advantage and efficiency

- Comparative efficiency of square and

Vee form threads

- Three year warranty

Range of Experiments

- Experimental determination of velocity ratio and comparison with calculated value

- Determination of variation with load of:

- effort

- friction

- efficiency

- Limiting efficiency of the machine

- Comparison of relative efficiency of Vee and Square thread forms

Description

This

is a simple wall mounted apparatus supplied with three interchangeable

screw and nut assemblies. Load is applied to a weight hanger attached

directly to the screw and the effort torque is applied by a weighted

hanger and cord passing over a low friction ball bearing pulley.

This

equipment is part of a range designed to both demonstrate and

experimentally confirm basic engineering principles. Great care has been

given to each item so as to provide wide experimental scope without

unduly complicating or compromising the design. Each piece of apparatus

is self-contained and compact. Setting up time is minimal, and all

measurements are made with the simplest possible instrumentation, so

that the student involvement is purely with the engineering principles

being taught. A complete instruction manual is provided describing the

apparatus, its application, experimental procedure and typical test

results.

|

|

|

|

Cam and Follower Apparatus Cam and Follower Apparatus

Features

- Low cost, effective teaching

- Self-contained

- Bench mounted

- Determines displacement diagrams

- Enables velocity and acceleration

diagrams to be derived

- Many types of cam motion can be studied

- Four follower types available

- Three year warranty

Range of Experiments

- To determine a graph of follower displacement against angular rotation of the cam

- To derive the velocity and acceleration diagrams, and determine the maximum acceleration of the follower

- To assess the effect of different cams and followers

- To compare experimental and calculated results

Description

The

displacement of an edge cam as it rotates through 360° is measured

using a dial gauge. The angular position of the cam is shown on a

graduated scale. A tangent cam with a 25mm diameter follower are

supplied as standard, and other cams and followers are available as

optional ancilliaries, as shown in the specifications.

A variety

of set ups is provided by a knife edge or roller follower in combination

with a tangent cam, a contant acceleration cam or a simple harmonic

motion cam.

A set of optional extras htm88j provides a flat

follower, lever and offset fittings and two more cams (one eccentrically

pivoted and one for uniform motion).

This equipment is part of a

range designed to both demonstrate and experimentally confirm basic

engineering principles. Great care has been given to each item so as to

provide wide experimental scope without unduly complicating or

compromising the design. Each piece of apparatus is self-contained and

compact. Setting up time is minimal, and all measurements are made with

the simplest possible instrumentation, so that the student involvement

is purely with the engineering principles being taught. A complete

instruction manual is provided describing the apparatus, its

application, experimental procedure and typical test results. |

|

|

|

Flywheel Apparatus Flywheel Apparatus

Features

- Low cost, effective teaching

- Self-contained

- Wall mounted

- Demonstrates:

a) Second Law of Motion

b) Energy storage

- Three year warranty

Range of Experiments

- To verify the second law of motion applied to a flywheel, ie the relationship between torque and angular accerleration

- To compare experimental and calculated moments of inertia of a disc

- To study the energy transformations and to demonstrate that a flywheel can be used to store energy

Description

A

steel disc 250 mm diameter and 30 mm thick is mounted on a shaft

running in ball bearings housed on a substantial wall bracket. A mark on

the flywheel and a pointer on the bracket enable the revolutions to be

counted and timed with the stop watch supplied. A cord, load hanger and

set of weights are provided.

This equipment is part of a range

designed to both demonstrate and experimentally confirm basic

engineering principles. Great care has been given to each item so as to

provide wide experimental scope without unduly complicating or

compromising the design. Each piece of apparatus is self-contained and

compact. Setting up time is minimal, and all measurements are made with

the simplest possible instrumentation, so that the student involvement

is purely with the engineering principles being taught. A complete

instruction manual is provided describing the apparatus, its

application, experimental procedure and typical test results. |

|

|

|

Small Flywheel Apparatus Small Flywheel Apparatus

Features

- Low cost, effective teaching

- Self-contained

- Wall mounted

- Demonstrates:

a) Second Law of Motion

b) Energy storage

- Three year warranty

Range of Experiments

- To verify the second law of motion applied to a flywheel, ie the relationship between torque and angular accerleration

- To compare experimental and calculated moments of inertia of a disc

- To study the energy transformations and to demonstrate that a flywheel can be used to store energy

Description

A

steel disc 150 mm diameter and 20 mm thick is mounted on a shaft

running in conical bearings housed on a substantial wall bracket. A mark

on the flywheel and a pointer on the bracket enable the revolutions to

be counted and timed with the stop watch supplied. A cord, load hanger

and set of weights are provided.

This equipment is part of a

range designed to both demonstrate and experimentally confirm basic

engineering principles. Great care has been given to each item so as to

provide wide experimental scope without unduly complicating or

compromising the design. Each piece of apparatus is self-contained and

compact. Setting up time is minimal, and all measurements are made with

the simplest possible instrumentation, so that the student involvement

is purely with the engineering principles being taught. A complete

instruction manual is provided describing the apparatus, its

application, experimental procedure and typical test results. |

|

|

|

Comprehensive Flywheel Apparatus Comprehensive Flywheel Apparatus

Features

- Low cost, effective teaching

- Self-contained

- Wall mounted

- Demonstrates:

a) Second Law of Motion

b) Energy storage

- Three year warranty

Range of Experiments

- To verify the second law of motion applied to a flywheel, ie the relationship between torque and angular accerleration

- To compare experimental and calculated moments of inertia of a disc

- To study the energy transformations and to demonstrate that a flywheel can be used to store energy

- To observe the effect of a change in moment of inertia

Description

A

steel disc 250 mm diameter and 30 mm thick is mounted on a shaft

running in needle roller bearings housed on a substantial wall bracket. A

mark on the flywheel and a pointer on the bracket enable the

revolutions to be counted and timed with the stop watch supplied. A

cord, load hanger and set of weights are provided.

The moment of

inertia can be altered by the addition of a disc and a ring of similar

masses. A vibrating arm provides an accurate means of measuring

acceleration, drawing a simple harmonic curve at a frequency of 5Hz onto

a strip of paper attached to the flywheel periphery. This is actuated

automatically as the flywheel starts to rotate.

This equipment is

part of a range designed to both demonstrate and experimentally confirm

basic engineering principles. Great care has been given to each item so

as to provide wide experimental scope without unduly complicating or

compromising the design. Each piece of apparatus is self-contained and

compact. Setting up time is minimal, and all measurements are made with

the simplest possible instrumentation, so that the student involvement

is purely with the engineering principles being taught. A complete

instruction manual is provided describing the apparatus, its

application, experimental procedure and typical test results. |

|

|

|

Spur Gear Lifting Machine Spur Gear Lifting Machine

Features

- Low cost, effective teaching

- Self-contained

- Bench mounted

- Two or three gear train

- Single or double purchase lift

- Determination of mechanical advantage,

velocity ratio and limiting efficiency

- Three year warranty

|

|

|

|

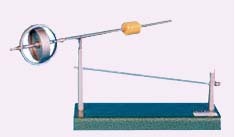

Model Gyroscope Model Gyroscope

Features

- Low cost, effective teaching

- Aids understanding of gyroscopic

precession through "hands on"

involvement

- High visual impact

- Three year warranty

Range of Experiments

- To

demonstrate visually precession and stability of a gyroscope, and to

assess the effect of direction of spin and speed of rotation

Description

It

is a model gyroscope which is put into motion by pulling a cord wrapped

around its shaft. It can be mounted on a counter weighted arm, stood on

a vertical pointed column, or on a sloping wire. All basic gyroscopic

phenomena can be demonstrated convincingly with this simple equipment.

This

equipment is part of a range designed to both demonstrate and

experimentally confirm basic engineering principles. Great care has been

given to each item so as to provide wide experimental scope without

unduly complicating or compromising the design. Each piece of apparatus

is self-contained and compact. Setting up time is minimal, and all

measurements are made with the simplest possible instrumentation, so

that the student involvement is purely with the engineering principles

being taught. A complete instruction manual is provided describing the

apparatus, its application, experimental procedure and typical test

results. |

|

|

|

|

|