Non Destructive Technology Instruments (NDT Instruments) |

Digital Portable Metal Hardness Tester Digital Portable Metal Hardness Tester

Application :

- Digital Portable Metal Hardness Tester is a small, light and portable tester.

- It is most suitable for testing of heavy, big or outdoor mental parts. Conforms to the Standard ASTM A956-02 Accuracy ± 6 HL Scales.

Technical Details :

| Accuracy |

± 6 HL |

| Scales |

HRC, HRB, HB, HV, HSD, MPa |

| Display |

Bright and clear LCD display with backlight |

| Testing direction |

All direction |

| Printer |

Mini thermal printer with IrDA (Cable no need) |

| Operating voltage |

4.5V (3 AAA batteries) |

| Operating environment |

Temperature 0 - + 40 oc Humidity : 20% - 85% |

| Storage environment |

Temperature : -30 - +80oc Humidity : 5% - 95% |

| Dimensions |

150mm*80mm*30mm |

| Weight |

Approx.200g |

| Accessories |

Display Unit, Impact Device D, Test Block, Mini-printer, Charger, Little Support Ring, Cleaning Brush , Printer Cable |

| Packing |

Plastic Box |

| Calibration |

Optional |

| Guarantee |

6 Months |

|

|

|

| |

|

Digital Portable Metal Hardness Tester (Without Printer) Digital Portable Metal Hardness Tester (Without Printer)

Features :

- Impact size, easy operation

- Wide measuring range in HLD, direct display of converted hardness values in HB, HRB, HRC,HRA, HV, HS

- High applicability, can be used for hardness testing of most metals

Technical Details :

| mpact device |

D integrated |

| Hardness scales |

HLD, HB, HRC, HRA, HV, HS |

| Tolerance |

± 6HLD(760 30HLD) |

| Memory |

99 average readings |

| Output |

RS232 to printer |

| Surface Roughness of Work piece |

1.6µm (Ra) |

| Min. radius of Work piece (convex / concave) |

Rmin = 50mm(with support ring Rmin= 10mm) |

| Min. Work piece weight |

2~5kg on stable support 0.05~2kg with compact coupling |

| Min. Work piece thickness with coupling |

5mm |

| Min. Thickness of hardened layers |

0.8mm |

| Charging time |

3h |

| Continuous working time |

60 h |

| Power |

Rechargeable Li-ion batteries |

| Operating temperature |

0~40oC |

| Overall dimensions |

155X24X55mm |

| Weight |

180 g |

|

|

| |

|

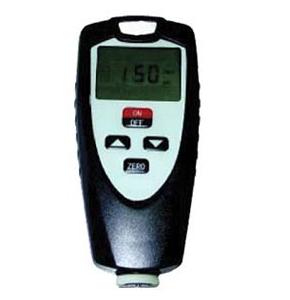

Digital Coating Thickness Gauge (Ferrous) Digital Coating Thickness Gauge (Ferrous)

Application :

- Used to check the coatings as Chrome , Paint , Galvanising , electroplating on Ferrous work peices.

- Used to check Non Ferrous coatings on Ferrous work peice.

Technical Details :

| Alternate names |

Dry Film Thickness Guage ( DFT Meter ) |

| Alternate Name |

Elcometer |

| Oerating principle |

magnetic induction (F) |

| Measuring range |

0-1000um |

| Resolution |

0.1/1 |

| Accuracy |

±1-3%n or ±2.5um |

| Min. measuring area |

6mm |

| Min. sample thickness |

0.3mm |

| Battery indicator |

low battery indicator |

| Metric/ imperial |

convertible |

| Power supply |

4x1.5V AA (UM-3) battery |

| Auto power off |

| Operating conditions |

0 to 45o |

| Dimensions |

160x68x32mm |

| weight |

250g(not including battery) |

| Optional accessories |

other range 0-200um to 15000um |

|

| Packing |

Plastic Box |

| Guarantee |

6 Months without abuse . 90 days on the Cable |

| Calibration |

Optional |

|

.jpg) |

| |

|

Digital Coating Thickness Gauge (Ferrous) Digital Coating Thickness Gauge (Ferrous)

Application :

- Used to check the coatings as Chrome , Paint , Galvanising , electroplating on Ferrous work peices.

- Used to check Non Ferrous coatings on Ferrous work peice.

Technical Details :

| Alternate names |

Dry Film Thickness Guage ( DFT Meter ) |

| Alternate Name |

Elcometer |

| Oerating principle |

magnetic induction (F) |

| Measuring range |

0-1000um |

| Resolution |

0.1/1 |

| Accuracy |

±1-3%n or ±2.5um |

| Min. measuring area |

6mm |

| Min. sample thickness |

0.3mm |

| Battery indicator |

low battery indicator |

| Metric/ imperial |

convertible |

| Power supply |

4x1.5V AA (UM-3) battery |

| Auto power off |

| Operating conditions |

0 to 45o |

| Dimensions |

160x68x32mm |

| weight |

250g(not including battery) |

| Optional accessories |

other range 0-200um to 15000um |

| Wit RS232 Data output port |

| Software & Cable Extra |

|

| Packing |

Plastic Box |

| Guarantee |

6 Months without abuse . 90 days on the Cable |

| Calibration |

Optional |

|

|

| |

|

Digital Coating Thickness Gauge ( Non Ferrous) Digital Coating Thickness Gauge ( Non Ferrous)

Application :

- Used to check the coatings as Chrome , Paint , Galvanising , electroplating on Non Ferrous work peices.

- Used to check Non Ferrous coatings on Non Ferrous work peice as Aluminum, Copper, Brass etc.

Technical Details :

| Alternate names |

Dry Film Thickness Guage ( DFT Meter ) |

| Alternate Name |

Elcometer |

| Oerating principle |

eddy current (NF) |

| Measuring range |

0-1000um |

| Resolution |

0.1/1 |

| Accuracy |

±1-3%n or ±2.5um |

| Min. measuring area |

6mm |

| Min. sample thickness |

0.3mm |

| Battery indicator |

low battery indicator |

| Metric/ imperial |

convertible |

| Power supply |

4x1.5V AA (UM-3) battery |

| Auto power off |

| Operating conditions |

0 to 45o |

| Dimensions |

160x68x32mm |

| weight |

250g(not including battery) |

| Optional accessories |

other range 0-200um to 15000um |

|

| Packing |

Plastic Box Packing |

| Guarantee |

6 Months |

| Calibration |

Optional |

|

.jpg) |

| |

|

Digital Coating Thickness Gauge ( Ferrous / Non Ferrous) Digital Coating Thickness Gauge ( Ferrous / Non Ferrous)

Application :

- Used to check the coatings as Chrome , Paint , Galvanising , electroplating on Non Ferrous work peices.

- Used to check Non Ferrous Coating on Ferrous Work peices.

- Used to check Non Ferrous coatings on Non Ferrous work peice as Aluminum , Copper , Brass etc.

Technical Details :

| Alternate names |

Dry Film Thickness Guage ( DFT Meter ) |

| Alternate Name |

Elcometer |

| Oerating principle |

magnetic induction/eddy current (F/NF) |

| Measuring range |

0-1000um |

| Resolution |

0.1/1 |

| Accuracy |

±1-3%n or ±2.5um |

| Min. measuring area |

6mm |

| Min. sample thickness |

0.3mm |

| Battery indicator |

low battery indicator |

| Metric/ imperial |

convertible |

| Power supply |

4x1.5V AA (UM-3) battery |

| Auto power off |

| Operating conditions |

0 to 45o |

| Dimensions |

160x68x32mm |

| weight |

250g(not including battery) |

| Optional accessories |

other range 0-200um to 15000um |

|

| Packing |

Plastic Box Packing |

| Guarantee |

6 Months |

| Calibration |

Optional |

|

|

| |

|

Digital Coating Thickness Gauge Digital Coating Thickness Gauge

Features :

- Economical model with F probe integrated

- Single point measurement mode

- Easy calibration on zero point

- 3 kinds of adjustable resolution for different application

Technical Details :

| Probe types |

F |

| Measuring methods |

magnetic induction |

| Measuring range |

0 to 1250µm |

| Display resolution |

1µm |

5µm |

10µm |

| Tolerance |

± (3%H+1) |

± (3%H+1.5) |

± (3%H+10) |

| H means the thickness of tested piece |

| Measuring condition |

Min. curvature radius (mm) |

Convexity 1.5 |

| Min. testing area diameter (mm) |

Ø7 |

| Critical thickness of substrate (mm) |

0.5 |

| Power supply |

Battery AAA (2pcs) |

| Working Temperature |

0-40oC |

| Dimensions |

110mmx50mmx23mm |

| Weight |

100g |

|

|

| |

|

Ultrasonic Thickness Gauge (UTG 100) Ultrasonic Thickness Gauge (UTG 100)

Application :

- Used for measuring thickness and corrosion of pressure vessels,chemical equipment,boilers,oil storage tanks,etc.in industries of petroleum,shipbuilding,power station,and machine manufacturing.

- This instrument is used for enclosed vessel , work peice , which cannot be cut to check the thikcness.

Technical Details :

| Alternate Name |

D Meter |

| Measuring range (metric/imperial) |

1.2-200mm,0.06-8inch |

| Oerating principle |

Ultrosonic |

| Materials measured |

only 11 types of materials, including steel, cast iron, aluminum, red copper, brass, zinc, quartz glass, polyethylene, PVC, gray cast iron, nodular cast iron |

| Lower limit steel pipes |

15x2.0mm, ?20x3.0mm determined by the transducer |

| Calibration block |

included |

| Resolution |

0.1mm |

| Accuracy |

±(0.5%n+0.1) |

| Power supply |

4x1.5vaa(UM-3) battery |

| Battery indicator |

low battery indicator |

| Operating conditions |

0 to 45o |

| Dimensions |

160x68x32mm |

| weight |

208g(not including battery) |

| Optional Accessories |

6M ø 6mm thin Material probe:Measuring range(steel): 1.0 50.0mm |

| Operating temperature |

-10 ~ +60 |

| 5M - 12high temperature probe |

Measuring range(steel): 1.0~225.0mm(normal temperature) |

| Measuring range(steel) |

4.0~100.0mm (high temperature) |

|

| Packing |

Plastic Box |

| Guarantee |

6 Months |

| Calibration |

Optional |

|

|

| |

|

Ultrasonic Thickness Gauge (UTG 101) Ultrasonic Thickness Gauge (UTG 101)

Application :

- Used for measuring thickness and corrosion of pressure vessels,chemical equipment,boilers,oil storage tanks,etc.in industries of petroleum,shipbuilding,power station,and machine manufacturing.

- This instrument is used for enclosed vessel , work peice , which cannot be cut to check the thikcness.

Technical Details :

| Alternate Name |

D Meter |

| Measuring range (metric/imperial) |

1.0-200mm,0.05-8inch |

| Oerating principle |

Ultrosonic |

| Materials measured |

any hard materials, including steel, cast iron, aluminum, red copper, brass, zinc, quartz glass, polyethylene, PVC, gray cast iron, nodular cast iron and other materials |

| Sound velocity |

500-9000m/s |

| Lower limit steel pipes |

15x2.0mm, ?20x3.0mm determined by the transducer |

| Calibration block |

included |

| Resolution |

0.1mm(TM8812C 0.01mm) |

| Accuracy |

±(0.5%n+0.1) |

| RS232C interface |

with RS232C |

| Power supply |

4x1.5vaa(UM-3) battery |

| Battery indicator |

low battery indicator |

| Operating conditions |

0 to 45o |

| Dimensions |

120x62x30mm |

| weight |

164g(not including battery) |

| Optional Accessories |

6M ø 6mm thin Material probe:Measuring range(steel): 1.0 50.0mm |

| Operating temperature |

-10 ~ +60 |

| 5M - 12high temperature probe |

Measuring range(steel): 1.0~225.0mm(normal temperature) |

| Measuring range(steel) |

4.0~100.0mm (high temperature) |

|

| Packing |

Plastic Box |

| Guarantee |

6 Months |

| Calibration |

Optional |

|

|

| |

|

Ultrasonic Thickness Gauge TT 100 Ultrasonic Thickness Gauge TT 100

Features:

- Portable size and easy operation

- Suitable for any metallic and non-metallic materials ultrasonic can go through

- Self-compensating of nonlinearity function is supplied for correction of pickup nonlineasity

- 10 measuring values recorded

- Optional 2.5MHz, 5MHz and 7MHz transducers are available

- Clear 4-Digit LCD display with backlight

- 5 pre-set sound velocities for repeating applications

- mm / inch selectable

Technical Details :

| |

TT100 |

TT110 |

TT120 |

TT130 |

| Measuring range |

0.75 -300.00mm (steel) |

| Measuring range for steel pipes |

Ø 20 3.0mm |

| Diameter of transducer |

Ø 10 (standard) Ø 6 (optional) Ø 12(optional) |

| Display resolution |

0.1mm |

0.01mm |

| Calibration |

4.0mm steel base plate integrated |

| Tolerance |

± (1%H+0.1) mm (H means the thickness of tested piece) |

| Measuring units |

mm/inch |

| Sound velocity range |

1000-9999m/s |

5900 m/s |

1000-9999m/s |

| Display |

4-Digital LCD with backlight |

4-Digital LCD |

| Surface temperature |

-10oc to +60 oc |

-10 oc to +300 oc |

-10 oc to +60 oc |

| Battery indicator |

Low battery voltage indication |

| Power supply |

2 Pcs. AA batteries 1.5V |

| Working time |

250 hours |

| Dimensions |

126mm X 68mm X 23mm |

| Weight |

Approx. 250g including batteries |

|

| Packing |

Plastic Box |

| Guarantee |

6 Months |

| Calibration |

Optional |

|

|

| |

|

Belt Tension Guage Belt Tension Guage

Application :

- Mainly used in belt tension measurement, can also be applied to measure the tension of objects such as tapes, wires. Widely applied in industries of automobile, textile, cables, wires, plastic films, paper, printting.

Technical Details :

| Measuring range |

0-750N | 0-120lb | 0-77Kg | 0-114Seems |

| Accuracy |

±5% |

| Belt state indication |

Low,OK,Hi |

| Resolution |

±1N (or1 least significant digit of other units) |

| Belt width |

36mm |

| Overload alarm |

750N |

| Max. load |

850N |

| Metric/Imperial |

| Auto power off |

| Pc interface |

RS-232C |

| Power supply |

4×1.5V AAA(UM-4) |

| Operating condition |

0 ~ 50?,< 85% RH |

| Dimension |

135×62×33mm (5.3×2.4×1.3inch |

| Net weight |

335g(not including batteries) |

| Optional Accessories |

Cable and Software for RS-232 and USB |

|

| Packing |

Plastic Box |

| Guarantee |

6 Months |

| Calibration |

Optional |

|

|

| |

|

Vibration Meter Vibration Meter

Application :

The instruments is used for measuring periodic motion, to check the imbalance and deflecting of moving machinery.

Is pecifically designed for present measuring various mechanical vibration. So as to provde the data for the quality control, run time and equipment upkeep.

To use the high-performance acceleration meter, realize the repetitiveness and accurate measurement. It has the function of testing axle bearing situation.

To chose a Vibration Meter one has to keep in mind the following : Velocity , Accelartion , Displacement , Frequency , RPM |

|

| |

|

Surface Roughness Tester Surface Roughness Tester

Features

- Pocket-size & economical price

- Large measuring range suitable for most materials

- Measures flat, outer cylinder and sloping surface

- Both Ra and Rz parameters in one instrument

- Features external calibration at keyboard

- Standard conform to ISO and DIN

- Rechargeable batteries, work while charging

- It is equipped with Li-ion battery and backlight

Technical Specification

| |

TR110 |

| Roughness parameter |

Ra, Rz |

| Tracing length |

6mm |

| Tracing speed |

1.0mm/sec |

| Cut-off lengths |

0.25mm/0.8mm/2.5mm |

| Evaluation length |

1.25mm/4.0mm/5.0mm |

| Measuring range |

Ra: 0.05-10.0µm Rz: 0.1-50µm |

| Tolerance |

±15% |

| Repeatability |

<12% |

| Filter |

RC analogue |

| Pick-up |

Piezoelectric |

| Radius and angle of the stylus point |

Diamond, Radius : 10± 2.5µm

Angle: 90 (+5 or -10 ) |

| Operating temperature |

0-40oC |

| Humidity |

<80% |

| Storing temperature |

-25 ~60oC |

| Vertilation |

Grade 3 |

| Power supply |

3.6V/2XNiMh-batteries |

| Backlight |

No |

| Charger |

DC 9V, 8 - 12 hours (recharging time) |

| Dimensions (LXWX H) |

125X73X26mm |

| Weight |

200g |

|

|

| |

|

Surface Roughness Tester Surface Roughness Tester

Features

- Applicable in production site, laboratory and workshop in factory

- Easy operation menu and large LCD display with backlight

- Li -ion rechargeable battery

- Pickup position indicator

- Conform to ISO standard, compatible with DIN, ANSI and JIS standard

- Advanced software for TR200 and TR220 is available

- Lots of delicate optional accessories are supplied making user’s measurement more efficient and easier

| Roughnes parameters |

Ra, Rz, Ry, Rq, Rt, Rp, Rmax, Rv, R3z, RS, RSm, RSk, Rmr, |

| Assessed profiles |

Primary profile (P) |

| Measuring system |

Metric, English |

| Display resolution |

0.01µm |

| Data output |

RS232 |

| Measuring Range |

±20µm, ±40µm, ±80µm |

| Cutoff length (L) |

0.25mm / 0.8mm / 2.5mm/Auto |

| Evaluation length |

1~5L (selectable) |

| Tracing length |

(1~5)L + 2L (selectable) |

| Digital filter |

RC, PC-RC, Gauss, D-P |

| Max. tracing length |

17.5mm/0.71inch |

| Min. tracing length |

1.3mm/0.051inch |

| Pick-up |

Standard pickup TS100, inductive, Diamond stylus radius 5µm , angle of stylus 90oC |

| Tolerance |

±10% |

| Repeapility |

<6% |

| Power |

Li-ion battery rechargeable |

| Dimensions |

141mm X56mm X48mm |

| Weight |

480g |

|

|

|